Core

The coring truck or skid steer mounted coring unit sets up and cores a 12″, 18″ or 24″ diameter hole through the roadway or sidewalk in just minutes.

The industry standard for keyhole technology is 18″ in diameter.

24″ diameter cores are often used when an application required additional room for access to the buried plant, or when long-handled tools required additional space.

12″ diameter cores can be used for “spot locates” or “daylighting” applications.

Extract the Core

Using the Utilicor core puller tool, which securely holds the core through the center pilot hole that was simultaneously cut during the coring process, the core is extracted from the roadway and safely set aside for future reinstatement

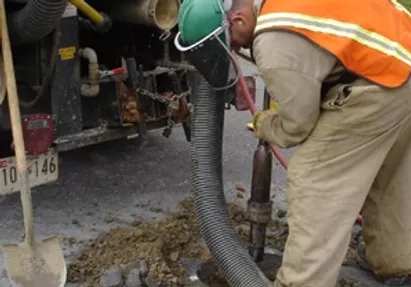

Vacuum Excavate

With clear access through the hard surface, vacuum excavation to expose the infrastructure and subsequent repair or inspection portion of the work can now go ahead.

Vacuum excavation used may be either “wet” or “dry”.

Backfill & Compact

Once the repair or inspection is complete, the hole is backfilled and compacted to an inch below the base of the pavement using either native fill or engineered fill.

The core and the cored hole are cleaned and ready for reinstatement

Dry Fit / Level the Core

To ensure a level fit and compensate for any irregularities on the bottom of the core, add a layer of pea gravel to the bottom of the hole.

Level the core with the pavement to about half an inch below the surface.

On thicker cores leave more of an offset. On shallower cores the offset from the pavement can be reduced.

Mix the Utilibond

Add one or two litres of water to the Utilibond pail and gradually add in dry Utilibond powder to the water in the pail.

Mix with a four bar mixing paddle for 2-3 minutes,

or until a smooth consistency with no lumps is achieved

Pour Utilibond

Carefully pour the Utilibond bonding compound slowly into the hole, being careful not to disturb the bed of pea gravel which was used to level the core.

Reinstate the Core

Using the core puller and a bar through the eye hook in the top of the core

puller to help share the load, slowly lower the core into the hole.

Gently rocking the core back and forth and apply gentle downward pressure.

Utilibond will ooze up through the kerf and completely surround the core.

Final Set of the Core

Once the Utilibond has flowed up around the complete circumference of the core, remove the core puller and the remaining Utilibond will come out through the center pilot hole.

Carefully level the surface of the core to the existing pavement.

Once the core is flush and level with the surrounding pavement stop pushing down. Double check for flushness relative to surrounding pavement.

Trowel off excess Utilibond from pavement surface.

Clean Up and Keep it Wet

Clean up any excess Utilibond around the hole with the trowel, and using a soft, wet, brush carefully smooth out the surface of the joint.

Keep the kerf line and the center pilot hole areas wet while the Utilibond sets.

Fill in any low spots in the kerf line or the center pilot hole with addional Utilibond as required.

Open Roadway

After 30 minutes (at 70° F) the Utilibond will have reached its full strength

gain capable of supporting a single wheel load of more than 50,000 lbs

(5 times the AASHTO H-25 Standard) and the roadway can be safely re-opened to traffic.

After the repair is complete the reinstatement is virtually invisible, and the

roadway has been restored to its pre excavation strength and load sharing

abilities in accordance with its original design.

The repair is both final and permanent.