Daylighting for Damage Prevention

Daylighting or potholing can be used everywhere but is most commonly found in advance of horizontal directional drilling work. These small access holes can be opened through both soft and hard surfaces to allow for visual confirmation of buried utilities in the bore line to reduce the chance of inadvertent hits to existing buried infrastructure. Not only does this process prevent damage, but a precisely cored and reinstated keyhole is better for the roadway, easier on the worker, causes less inconvenience to the public and saves thousands of dollars in paving restoration costs.

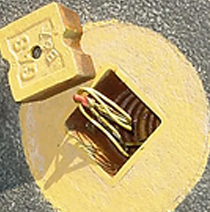

Cathodic Protection

Extending the life of buried metal pipes by connecting them to sacrificial anodes is an easy keyhole application and one every gas or water utility should adopt. Using keyhole coring and vacuum excavation equipment to access pipes buried under pavement and long handled tools to clean the pipe and weld on the connection is simple, safe and reliable. The process is fast and efficient and the comparative pavement restoration costs are a fraction of conventional methods and can save more than $1,000 per hole.

Keyhole Excavation and Anode Installation

PDF NASTT.

Cast-iron Joint Leak Repair

Some cast iron gas pipes have been in the ground for 100 years or more and are prone to leaks between the bell and spigot. These leaky joints can be repaired by encapsulating the joint with a boot or sealing it with an anaerobic sealant using long handled tools through a cored keyhole. The process has been used for more that 25 years and the reinstatement of the core can save entire streets from being ripped up and repaved.

Subsurface Utility Engineering

Visually identifying and measuring the exact location of buried infrastructure is an essential element of the mapping of buried infrastructure before final engineering drawings are completed. SUE can save more that four dollars for every dollar invested. But opening a hole in the pavement using conventional excavation methods that require extensive and costly pavement repairs afterwards can wipe out these savings very quickly. Using keyhole coring and reinstatement allows SUE companies to get in and out without damaging the roadway, while still obtaining the exact utility depth and location measurements required for “A” level SUE work. Keyhole coring and reinstatement makes the SUE process faster and even more cost-effective.

Service Cut-offs

Cutting off a service from the main, or sectionalizing the pipe for safety reasons after a main has been abandoned, is a perfect application of the keyhole process as many gas utilities look to reduce the punitive costs of pavement rehabilitation and large cut-backs imposed by municipalities for these small openings. Tooling for these applications is readily available, and processes have been well developed over the years to cover a multitude of different types of service cut-offs using the keyhole process.

Connecting Service Laterals

Connecting a new service lateral through a keyhole to a main that had been trenchlessly installed or rehabilitated is a key element in helping to keep, what was supposed to be a “no-dig” or “trenchless” process “trenchless”… or at least as close to “trenchless” as possible. After a new main is directionally drilled and the new pipe pulled through, the service laterals can be reconnected through a keyhole using bolt-on or electrofusion saddles. The pavement core can then be reinstated as an almost invisible permanent pavement repair rather than scarring the neighbourhood with a checker-board of small, unsightly, square-cut excavations that will subsequently need to be milled and overlaid.

Valve Box Repair or Replacement

Installation of a valve box or test station using the keyhole process results in a precise, circular-cored opening and a perfectly flush finish with the surrounding roadway. There are no overcuts one typically finds when using a road saw and a jack hammer, and the smaller cored openings can be sized to exactly fit the new valve box. This application works for both gas and water utilities. For valve boxes that have sunk, or that have been paved-over, the coring and reinstatement process is also a perfect solution when these need to be reset level with the surrounding pavement.

Pipeline Inspection

Insertion of cameras for pipe integrity inspections or to identify and map the location of bell joints in advance of keyhole bell joint repairs, can be done through an 18-inch diameter keyhole, into a live gas main. The cameras can travel at least 150 feet in each direction in a cast iron or steel main and 250 feet in each direction in a PE pipe, enabling you to inspect the condition of the pipe and locate and map joints and fittings.

Horizontal Directional Drilling through a Keyhole

TT Technologies has developed an ultra-compact horizontal directional drilling unit than can be launched and operated through a 24-inch diameter cored keyhole. Although slower than conventional drills, this application could have real application in congested urban centers where the new service can be installed from the main in the center of the street to the curb line without ripping up the road. At the curb other devices can take over to reach the house, With the Grundopit-K’s automated drilling feature, the operator simply loads rods into the handling chamber and at the press of a button the rod is lowered and loaded into the drill head. The drill process can be done in an automatic mode for straight bores and can be switched to a manual mode when steering corrections are needed.

Pipeline Integrity Inspection

The Rock Solid Group, based in Australia, has recently developed a unique tool using Broadband Electro-Magnetic (BEM) sensors to assess the internal integrity and wall thickness of pipeline systems from the outside of the pipe. This device, that can be used in both the water and the gas industry, can be launched and operated through an 18-inch diameter cored keyhole